KNITTING

With roots firmly planted in the knitting industry, Safer Textiles uses skills and expertise developed over our 40+ year history to turn premium yarns into high quality fabrics that drive bottom line value. From interlocks to jacquards and jerseys, to piques and pontes, and specialty knits, Safer Textiles has experience knitting a wide variety of materials for a broad range of markets. In addition, a careful inspection of each run of fabric assures that greige goods meet, and in many cases, exceed strict industry standards.

YARNS AVAILABLE:

KNITS:

- 100% Polyester / Polyester Blends

- Microdenier

- 100% Nylon / Nylon Blends

- Copper

- Silver

- Inherent Antimicrobial

- All Spandex Blends

- 100% Cotton / Poly Cotton

- Nomex / Nomex Blends

- Recycled Yarns

- Carbon

- Polypropylene

- Inherent Wicking

- Inherent FR

FINISHING

The company’s state of the art equipment constructs fabric to exact specifications, and our quality assurance team performs all tests required prior to shipment.

Our preparation processes include:

- Desizing

- Bleaching

- Scouring

Our surface finishing processes include:

- Napping

- Sueding

- Sanding

Our chemical finishing treatments include:

- Flame Retardant

- Moisture Management

- Stain and Soil Resistant

- Durable Water and Oil Repellent

- Antimicrobial

- Shrinkage Control

- Elastomeric Finishing

- Crease Resistant

WOVENS:

- 100% Cotton (up to 18 oz. / sq. yard)

- 100% Polyester and Poly Cotton Blends

- Nylon: From Lightweight Ripstop to 1050 Denier Coated Ballistic Fabrics

DYEING

Safer Textiles’ dyeing department makes the fabric a colorful reality. Our computerized dye lab can color match your fabrics, creating the desired shade sought by your clients.

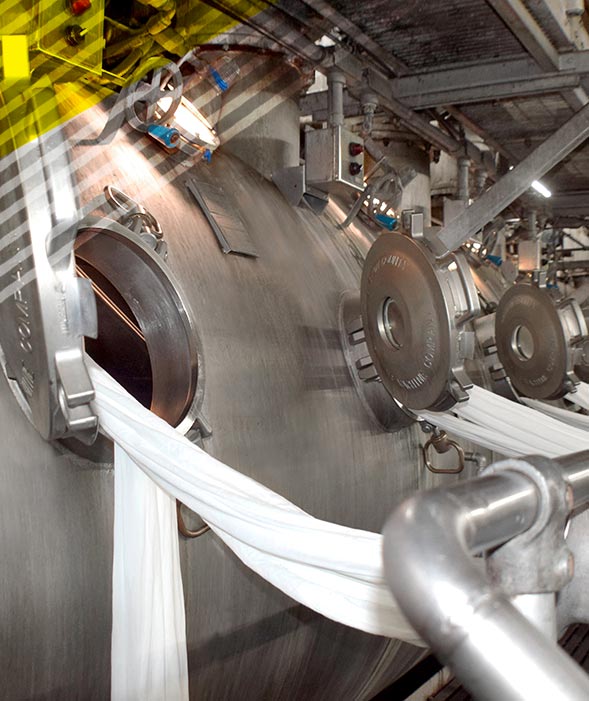

The company utilizes 25+ modern computer dyeing machines (e.g., jets, soft flows, jigs, atmospheric beams), with capabilities reaching up to 4,000 pounds per lot. Safer Textiles has the ability to dye different kinds of fabrics under pressure or through atmospheric procedures using disperse, reactive, and numerous other dyes, thus providing clients with a variety of possibilities and customizable solutions.

Keeping with the highest standards in the industry, Safer Textiles utilizes a Datacolor 800 Spectrophotometer to measure color consistency in our dye lot productions. This state of the art measurement system enables Safer Textiles to transfer QTX files directly to customers and leverage historical data from past lots to ensure color consistency.

COATING

Safer Textiles’ coating line complements the company’s dyeing and finishing capabilities. Through a knife blade process, a water-based polyurethane is applied to wovens of various weights, which are then cured on a 90-foot, 10-zone thermal range in order to ensure that our products meet or exceed all required specifications. Additional finishes such as durable water repellents and flame retardants can be added during this process, which can be applied to both prints and solids. As a result, Safer Textiles can manage all of its clients’ needs under one roof while offering the highest quality products available in the industry.